Rebonded Foam: What Is It and What Are the Benefits?

Rebonded foam is a relatively new product on the market, but it has been gaining in popularity rapidly because of its many benefits. So what is rebonded foam, and why should you consider using it in your business? Keep reading to find out!

Bonded Foam vs Rebonded Foam

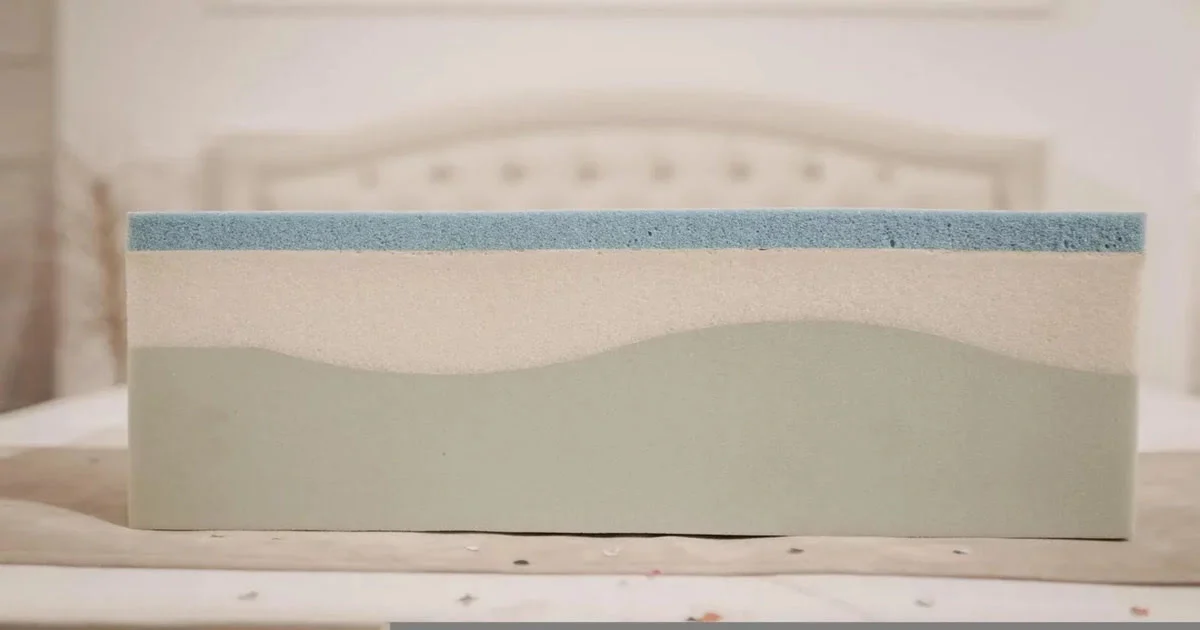

Bonded foam is a type of mattress made from multiple layers of foam bonded together. It is designed to provide support and comfort while still being lightweight and durable.

The foam used in bonded foam mattresses is typically high-density, meaning it will maintain its shape and not sag over time. These mattresses also typically have a lower price point than other types of mattresses, making them a good option for budget-conscious shoppers.

However, bonded foam mattresses may not be as supportive as other types of mattresses and may not provide the same level of comfort.

Rebonded foam, also known as reconstituted or rebonded polyurethane foam, is a type of rebonded foam mattress that is made from recycled scraps of regular polyurethane foam.

The scraps are broken down into small pieces and recombined with an adhesive to create a new, stronger piece of foam. A Rebond foam is often used in mattresses, furniture cushions, and car seats.

It is also popular in the manufacturing of yoga mats and other exercise equipment.

Rebonded foam has several benefits over regular polyurethane foam, including being more durable, supportive, and comfortable. It is also more environmentally friendly because it uses recycled materials. However, the rebonded foam may be more expensive than regular PU high-density flexible foam.

What is Rebonded Foam?

Rebonded foam is a high-density foam that is made from recycled pieces of low-density foam. The recycled foam is bonded together with adhesive to create a single piece of high-density foam using multiple densities. Rebonded foam is often used in mattresses, upholstery foam in furniture, and automotive applications.

It is also commonly used as padding for exercise equipment. Rebonded foam has many advantages over other types of foam. It is more durable and has a longer lifespan than other types of foam. In addition, it is resistant to pests and mold, and it does not absorb moisture.

Rebonded foam is also easier to clean than other types of foam. However, rebonded foam is not as soft as other types of foam, and it does not contour to the body as well. As a result, it may not be as comfortable to sleep on. rebonded foam is also more expensive than other types of foam.

What are the Benefits of Rebond Foam?

The benefits of rebond foam include being more durable, supportive, and comfortable than other types of foam. Rebond foam is also more environmentally friendly because it uses recycled materials. However, the rebond foam may be more expensive than other types of foam.

The bottom line is that rebond foam is a high-quality, durable product that has several advantages over other types of foam. If you are looking for a mattress, furniture, or automotive padding that is supportive and comfortable, the rebond foam may be the right choice for you. However, if you are looking for a softer, more contouring foam, the rebond foam may not be the best option.

Rebond Foam vs PU Foam

Pu Foam mattresses are made of a type of polyurethane foam that is comfy and has a long-lasting life. Pu Foam offers good support to the body and does not get easily deformed.

On the other hand, Rebond Foam mattresses are made of recycled foams that are bonded together with adhesive chemicals. They offer good support to the body as well and are quite durable.

The main difference between Pu Foam and Rebond Foam lies in their manufacturing process. Pu Foam is made of a single piece of foam that is cut into shape, while Rebond Foam is made of multiple pieces of foam that are bonded together.

This makes Pu Foam more expensive than Rebond Foam. Another difference between the two lies in their comfort level; Pu Foam is more comfortable than Rebond Foam as it conforms to the shape of the body more easily.

Pu Foam is a type of polyurethane foam that consists of a variety of foams synthesized using polyols and isocyanates. It is open-cell foam, usually of medium to low quality, with a shorter lifespan than other foams, but with a wide variety of uses.

Pu Foam has a simple forming process and polyurethane resin has excellent adhesion properties. The term polyurethane is also known as PU, urethane, or reflex foam.

Pu flexible Foam is used in many applications such as cushions, mattresses, insulation, acoustic foam for soundproofing, and packaging. Pu flexible foam is also used in the automotive industry for seat cushions, headrests, armrests, dashboards, and trim panels.

Pu Foam is also used in the construction industry as insulation in walls and ceilings. Pu Foam is also used in the footwear industry for soles, insoles, and uppers.

Rebonded Foam is a Green Solution

Rebounded foam, or rebonded polyurethane foam, is made by combining small pieces of recycled foam and bonding them together with adhesive.

The resulting material is strong and resilient, making it ideal for a variety of applications such as flooring, packaging, and insulation. Rebounded foam also has environmental benefits as it helps to reduce land pollution.

When properly disposed of, Rebonded foam can be recycled and used to create new products. As a result, Rebonded Foam is an eco-friendly option for those looking for a sustainable solution.

What is PU Foam?

PU foam is essentially used in the manufacture of different products like blankets, furniture, car seats, thermal insulation, and packaging materials. Polyurethane foam is also known as foam rubber. It is a wide range of foams that are made of latex, neoprene, and silicone.

The two types of this foam are flexible and rigid polyurethane foam, both of which are essential for PU foam. The flexible kind is typically used in household products like mattresses, sofas, and car seats while the rigid form is utilized for purposes such as thermal insulation.

Pu Foam has several benefits which make it ideal for many different uses. It is very lightweight yet durable and has excellent resistance to both water and fire. In addition, it is also an excellent insulator against both heat and cold.

Pu Foam is also very easy to work with and can be shaped into any form necessary. As a result, it is an extremely versatile material that can be used in a wide variety of applications.

Pu foam is composed of several components which are important for its formation, such as polyols, di-isocyanates, blowing agents, surfactants, and stimulants.

The production process is divided into polymer system manufacturing and foam production steps. In the manufacturing of Pu foam, the first step is to assemble the components by means of a mixing head batching system.

The next steps involve the reaction of these components to form Pu foam.

The main reactive components in this process are polyols and chemical blowing agents. As Pu foam is formed, it expands and becomes light and porous. This final product has a wide range of applications due to its properties, such as thermal insulation, sound absorption, and shock absorption.

What’s the Difference Between PU Foam and Rebonded Foam?

The lifespan of PU foam is 1.5 to 6 years whereas rebonded foam has a longer lifespan of about 15 years.

The choice of colors is another distinction. PU foam comes in many different colors, it really is up to the foam factory and the dye they use, whereas rebonded foam is available in a variety of colors.

PU Foam is used in the production of furniture, packing, and shipping. It’s also used to make dog beds and car seats. The applications of Rebounded foam are in-vehicle seating, carpet padding, and gymnasium equipment, among other things.

Polyurethane foam is produced with the aid of liquid streams, whereas Rebonded foam is formed from recycled scrap foam. The former is well-known for its comfort and springiness, while the latter is renowned for its toughness and firmness. All work well if you want to produce a high-quality spring mattress.

Rebonded Foam Machines

Rebonded foam machines are an essential piece of equipment for any business that uses foam insulation. These machines take shredded foam and Bond it back together to create a dense, solid block of Rebonded foam.

Rebonded foam is pressure-molded and has a very high R-value, making it ideal for use in a variety of applications. Rebonded foam machines can be used to create Rebonded foam blocks of any size or shape, and the blocks can be used to insulate walls, floors, ceilings, and even roofs.

Rebonded foam is an excellent way to reduce energy costs and make your home or office more comfortable. If you are thinking about adding Rebonded foam to your insulation project, consider using a Rebonded foam machine.

A word from Wijaya Foam!!

If you’re in the market for rebonded foam, we sell in bulk or if you want to add it to your foam factory we can assist with helping you learning the process.

In addition to our standard colors, we also offer flexible foam equations that will help you create the desired foam density that serves your clientele well while promoting higher profits for your business.

Contact us today to learn more about how we can help you get the most out of your rebonded foam needs!

When you order our Foam equations we work with you every step to assure you understand how to produce high-quality foam. We also offer in-person training. Order Now!

Yanie Wijaya

CFO @ wijayafoam.com

Yanie Wijaya is a leading expert in the foam mattress industry with over 15 years of experience. As the owner of Wijaya Foam and key brands like Asia Deluxe and Eversoft Rebonded, she has shaped mattress manufacturing across Southeast Asia. Outside of her professional life, Yanie enjoys motherhood and Korean cinema. Her deep industry knowledge makes her a trusted authority in foam mattress innovation.